Creating Wood Type

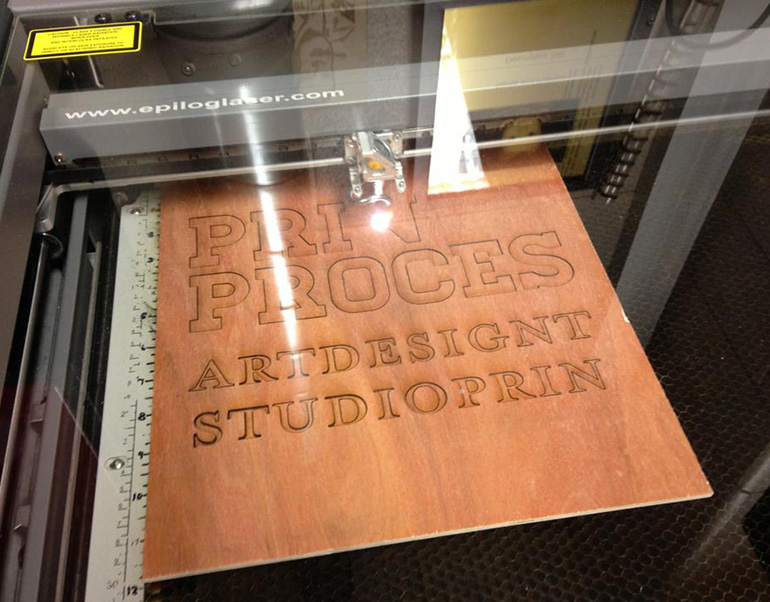

A fellow faculty member, James Shurter, and I share an interest in wod type and letterpress printing. We wanted to find a way to allow students to create their own typeface and produce it for printing on a traditional letterpress. We received an innovation grant from the college to pursue the project. We did some research on creating wood type and decided to each run our own tests to produce type. After visiting the FabLab on our campus which is loaded with all kinds of great gadgets, I decided to try to replicate closer to the original while he was going to use the laser cutter.

To start, I had cherry wood that was kiln dried milled to type high and cut into manageable pieces. I could not get the same center cut rounds that were originally used, but this was as close as possible. I then created an Illustrator of the font I planed to use, Blanche from the The Lost Type Coop. I had to make a few minor modifications to it so that the router would be effective in making the type. It needs a .25″ rounded corner on all inside corners. The Blanche font already has a number of rounded edges so it didn’t look to bad after the modifications. I also altered the q so that it would better fit on press. I flipped the file to reverse and then sent it off to the guys in the FabLab. They loaded the file and tweaked in the computer to better adjust for the router. The ShopBot they have loads the digital file and determines what cuts need to be made and when. It cuts relatively quickly, about a half an hour per half of the alphabet. I had to then cut it down using a table saw, miter saw, and band saw. The pieces need a light sanding and then varnish.

The final letters are about 4.5″ tall. It cost me about $20.00 for the two pieces of wood and my time in the FabLab only cost me a batch of brownies. I tried to find out what it costs for non faculty people, but he couldn’t commit to a price. I think there’s potential in this method. The type did hold up on the press and I do continue to use it with my classes. I am limited a bit by the router, but it seems simpler because I don’t have to glue anything like my colleague using the laser cutter. We ultimately decided to use the laser option with the students because it allowed them more flexibility with their designs.